Computational Fluid Dynamic (CFD) Modeling

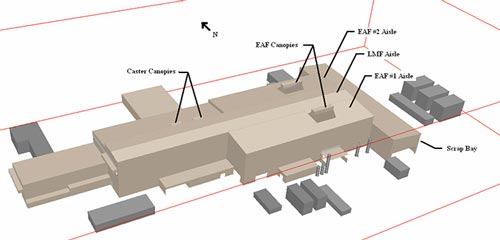

GCT utilizes proprietary and in-house mathematical models for process simulation to optimize system design of gas handling systems and secondary fume control systems in process plants. We use Computational Fluid Dynamic (CFD) models as an effective design tool to predict the performance of gas handling systems for process plants. CFD provides the means to compare the relative performance of several design scenarios. Specific benefits of our CFD modeling techniques include:

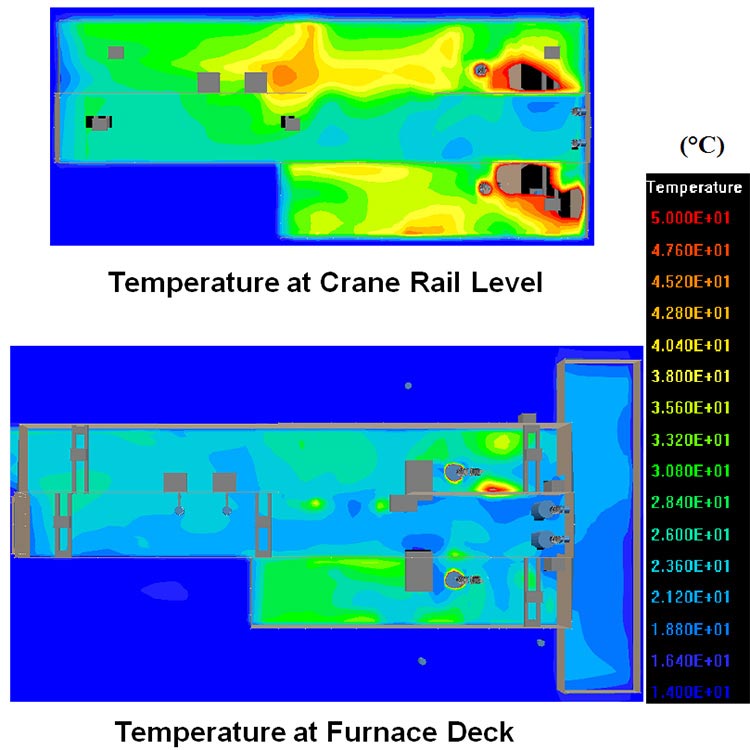

Predicting heat and contaminant exposure levels

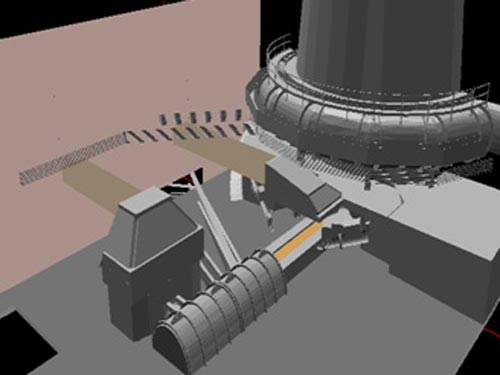

Evaluating performance of ventilation systems in process plants

Predicting airflow patterns and contaminant migration paths

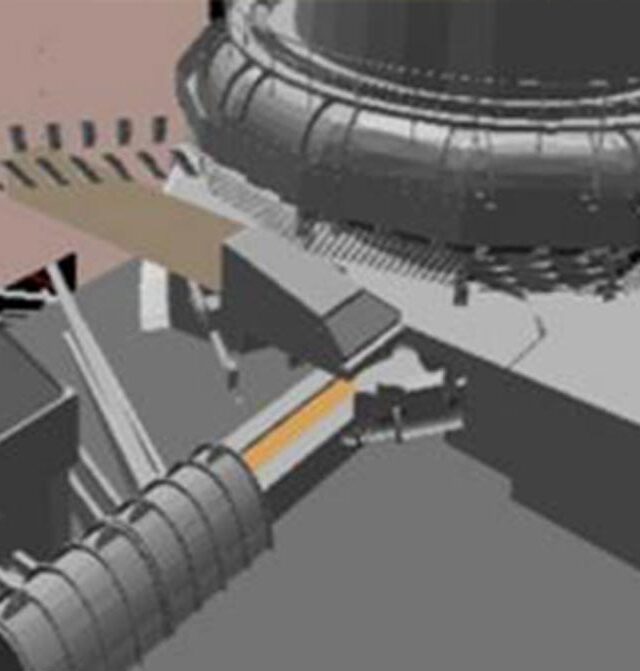

Optimizing primary and secondary capture hood performance

Predicting and optimizing process gas mixing and combustion

Evaluating burner configuration and selection

Benefits of CFD:

Provides a Quantitative Estimate of Fume Capture

Provides a Quantitative Estimate of Temperature at any Elevation Inside Building

Model Validated Using Field Measurements

Able to Test Many Scenarios Efficiently

Effects of Wind Direction and Ambient Temperature on Cross Drafts and Hood Fume Capture Performance

Let's Make

The World a

Better Place,

Together

Gas Cleaning Services

GCT provides gas cleaning services such as process gas handling, fugitive emission control, bulk material handling, and more.