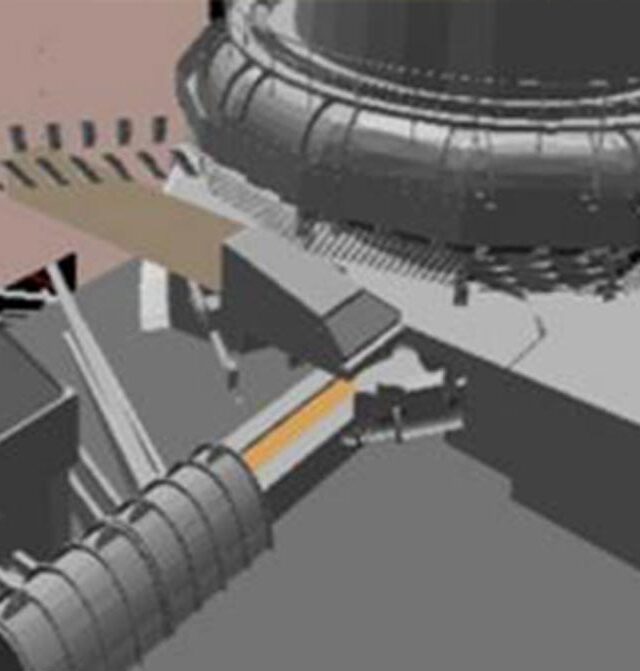

Drummond-GCT™ Water Cooled Hood

Factors affecting primary hood gas collection efficiency:

Mouth angle

Hood / door configuration

System draft

Infiltration rate

Apron plate/hood gap

Door/hood gap

Hood geometry

Hood cooling system (panel design, water velocity)

Downstream infiltration

Physical condition of hood

Typical Primary Hood Problems:

Converter mouth blowing angle is too close to vertical

Door/hood joint is blasted by hot gas

Excessive gas leakage

To prevent leakage, the system draft has to be increased; this results in excessive infiltration

Water leaks (corrosion, erosion, insufficient water flow/velocity, crane impacts)

Design advantages of Drummond-GCT Hood Design:

Simple, low cost fabrication

Rugged, durable design

Low maintenance costs

No accretion build-ups

Long panel life

Easy installation

Simple operation

Closed circuit water system (minimizes evaporation and build-up of dissolved solids, reduces opportunity for oxygen entrainment, minimizing internal corrosion)

Let's Make

The World a

Better Place,

Together

Gas Cleaning Services

GCT provides gas cleaning services such as process gas handling, fugitive emission control, bulk material handling, and more.